The Future of Industrial Packaging: Trends to Watch

Introduction to Industrial Packaging Trends

The industrial packaging industry is undergoing a transformative phase, driven by technological advancements and changing consumer expectations. As businesses adapt to these shifts, understanding the emerging trends becomes crucial for staying competitive. This blog post will explore the future of industrial packaging and highlight key trends to watch.

Sustainability Takes Center Stage

One of the most significant trends in industrial packaging is the growing emphasis on sustainability. Companies are increasingly focusing on reducing their environmental impact by adopting eco-friendly materials. This involves using recycled materials, biodegradable options, and minimizing packaging waste.

Additionally, innovations in sustainable packaging are not just limited to materials. Many companies are redesigning their packaging systems to be more efficient, using less material without compromising quality or safety.

Smart Packaging Solutions

The integration of technology into packaging is another trend revolutionizing the industry. Smart packaging solutions, such as RFID tags and QR codes, provide real-time tracking and monitoring of products. This not only enhances supply chain efficiency but also improves customer engagement by providing them with detailed product information.

Customization and Personalization

With the rise of e-commerce, the demand for personalized and customized packaging has increased. Consumers now expect packaging that reflects their individual preferences and enhances their unboxing experience. This trend is pushing businesses to invest in flexible packaging solutions that can adapt to different needs.

Furthermore, personalized packaging helps brands stand out in a crowded market, creating a unique connection with customers and boosting brand loyalty.

Automation and Efficiency

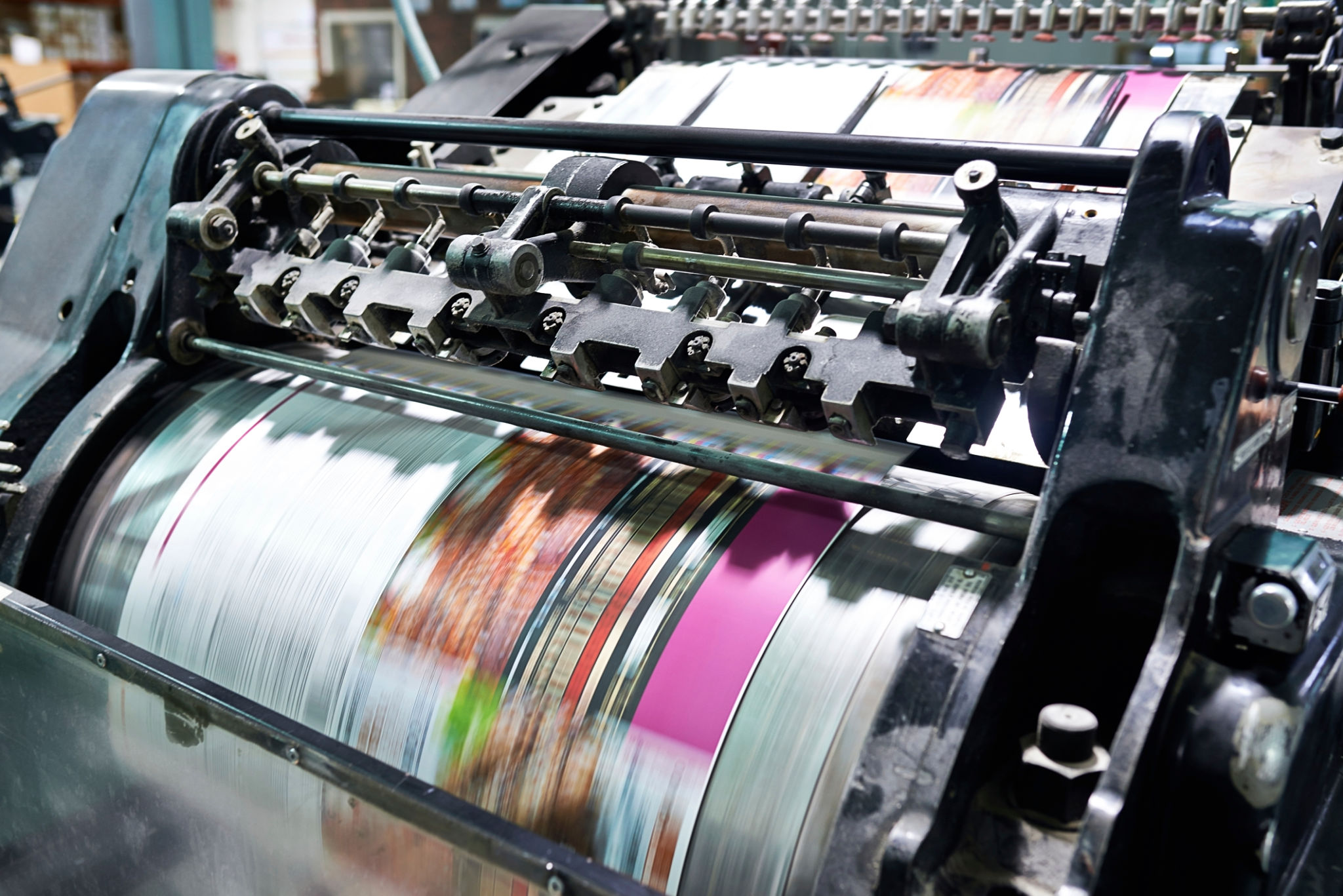

Automation is playing a crucial role in enhancing the efficiency of packaging processes. Automated packaging systems reduce manual labor, increase speed, and improve accuracy. This is particularly important in industries that require high-volume packaging.

Moreover, advancements in robotics and AI are paving the way for even more sophisticated automation solutions. These technologies enable businesses to streamline operations and reduce costs, ultimately leading to greater profitability.

The Rise of Protective Packaging

As e-commerce continues to grow, the need for protective packaging solutions is becoming more critical. Companies are investing in advanced materials and designs that ensure products arrive safely at their destination. Protective packaging not only prevents damage but also enhances customer satisfaction.

Some popular innovations in this space include air cushions, foam inserts, and custom-fit solutions that provide superior protection during transit.

Conclusion

The future of industrial packaging is dynamic and full of opportunities. By embracing these trends, businesses can not only improve their packaging processes but also enhance their brand image and customer satisfaction. Staying informed and adaptable is key to thriving in this evolving landscape.