How to Choose the Right Transport Packaging for Fragile Goods

Understanding the Importance of Proper Transport Packaging

When it comes to shipping fragile goods, selecting the right transport packaging is crucial. Proper packaging not only ensures the safety of your products but also enhances your brand's reputation by delivering items in perfect condition. As an essential part of logistics and distribution, choosing the right packaging can reduce breakage and minimize returns, ultimately saving you time and money.

Given the variety of options available, deciding on suitable packaging might seem daunting. However, by considering a few key factors, you can select packaging that protects your items while maintaining cost-effectiveness.

Assessing the Fragility of Your Goods

Before selecting transport packaging, it's vital to assess the fragility of your goods. Items like glassware, electronics, and ceramics require different protection levels compared to non-fragile items. Consider the material, weight, and dimensions of each product. Additionally, understanding the shipping environment—whether by air, sea, or land—will influence your packaging choices due to varying levels of handling and environmental conditions.

Once you assess the fragility, you can determine if specialized packaging solutions are needed. For example, electronics might require anti-static packaging, while glass items could benefit from foam inserts or bubble wrap for added cushioning.

Choosing the Right Packaging Materials

The choice of packaging materials plays a significant role in protecting fragile goods. Some popular materials include:

- Bubble Wrap: Offers cushioning and protection against shocks.

- Foam Inserts: Customizable and ideal for absorbing impact.

- Packing Peanuts: Lightweight and excellent for filling voids in boxes.

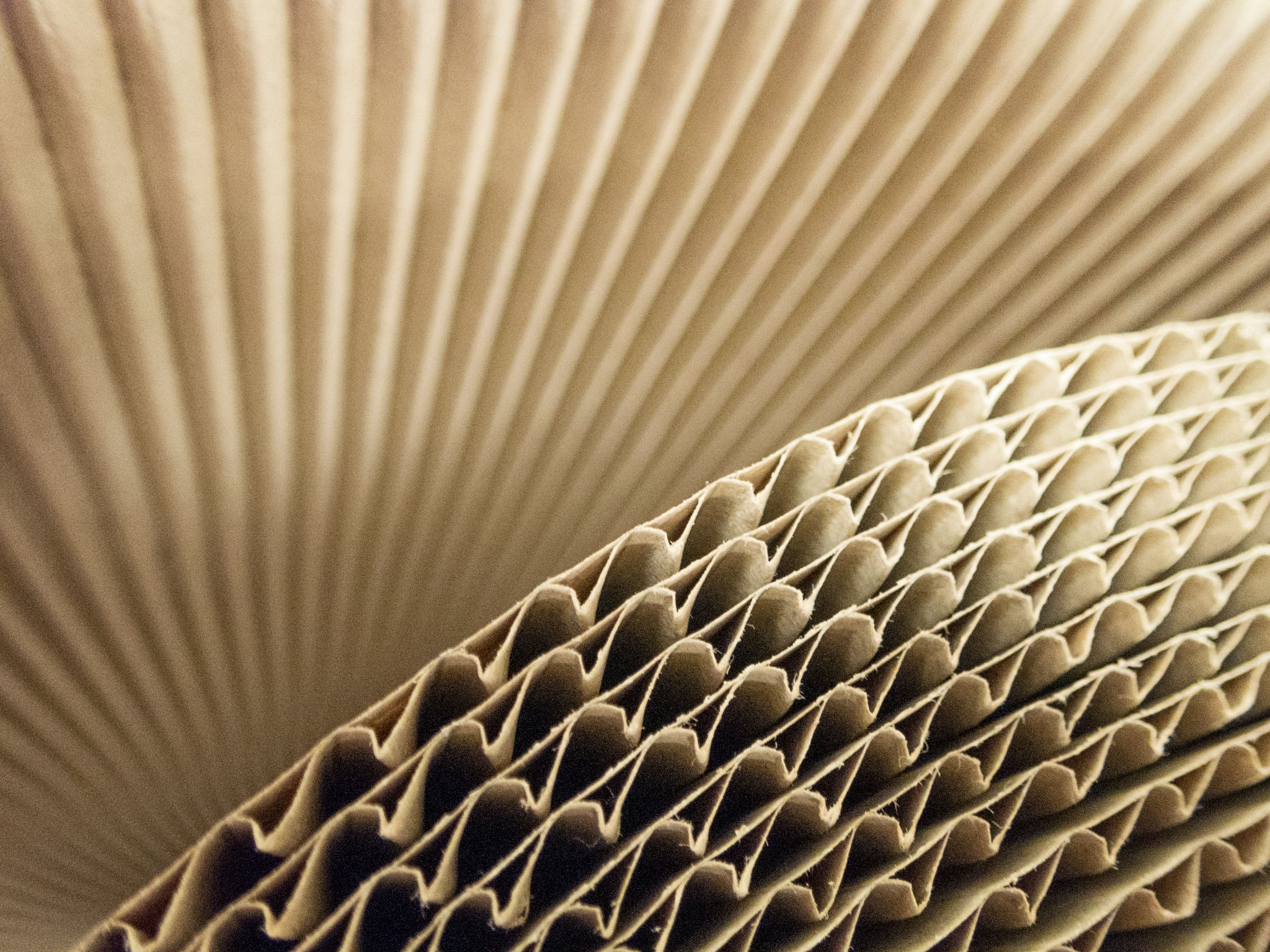

- Corrugated Boxes: Durable and available in various sizes for added stability.

Understanding Packaging Design

The design of your packaging should align with the level of fragility and shipping conditions. Consider custom-designed packaging if your products have unique shapes or sizes. This approach ensures a snug fit, reducing movement during transit. Additionally, using double-layered boxes for extra protection can prevent damage from external pressure.

Innovative design solutions like molded pulp or air pillows can also provide enhanced protection while being environmentally friendly. Ensuring your packaging is easy to open without compromising safety is another aspect to consider.

Cost-Effectiveness and Sustainability

While protecting your goods is paramount, it's also essential to balance cost-effectiveness with sustainability. Investing in high-quality packaging might incur upfront costs but can lead to savings by reducing damage-related expenses. Moreover, opting for recyclable or biodegradable materials can enhance your brand's sustainability efforts and appeal to environmentally conscious consumers.

Testing Your Packaging Solutions

Before finalizing your packaging choice, conduct thorough testing to ensure its effectiveness. Simulate transportation conditions to identify potential weaknesses in your packaging design. Drop tests, compression tests, and vibration tests are effective methods to assess durability and protection levels. Gathering feedback from customers regarding their unboxing experience can also provide valuable insights for improvements.

By following these steps, you can make informed decisions about transport packaging for fragile goods, ensuring safe delivery and satisfied customers.